Manifold Edges

Surface Facing

Material Thickness

Material Optimization

Manifold edges are probably what people struggle with the most when they start out. It's a big, scary word that actually doesn't mean very much.

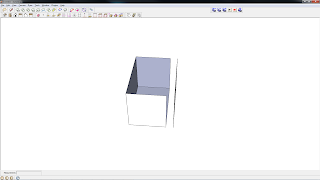

It's basically saying that all the edges of a model must be connected. Imagine you have a box. The box must be connected on all sides in order to hold liquid, right? Something like this would be NON-MANIFOLD:

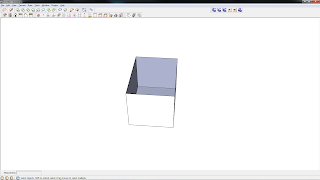

The edges aren't connected, so the the computer (and therefore the printer) cannot build the shape. Now, this is an obvious example. Lets look at one that is less obvious:

Now, you may be asking what's wrong with this. After all it's an open box, right? Well, not exactly. See, a line and surface has 0 thickness. That is, it doesn't actually exist. The computer is simply telling you that you're working with a surface this size - but the surface has no thickness yet.

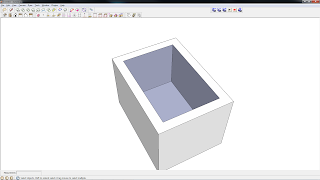

In the real world, everything has a thickness. Even paper and atoms can be measured, so we have to make the same true of our models. Lets give our box a thickness:

Alright, now our box has thickness. It's ready to print, right? No. Now we address the second problem. 3d printers need to know what surface is on the outside and which is on the inside. You'll notice the box has a blue-grey color and a white color. The blue-gray marks the interior of an object, and white the outside of it.

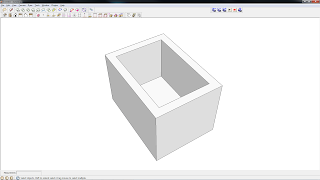

The rule of thumb is to make certain everything on the outside is white:

Alright, now this box is 100% 3d printable!

But, if you were to put it up on the market, it would probably cost around $10,000. Why? Material thickness. Shapeways charges by the amount of material required to print the model. For this reason, you'll need to make certain that your model is A) The size you want it to be and B)hollowed out (material optimization).

I'm not going to get into hollowing models because that is a full post on its own.

But let's discuss material thickness. Each material has a minimum thickness. If the material is too thin, it will break when it is cleaned or during shipping. Don't worry, Shapeways will detect the problem and reject your model so you don't waste money. But it won't tell you where the problem with thickness is.

There are a lot of different materials, and I won't go into them all right now. You can find this list (along with a lot of other helpful tips) here.

A plugin that is extremely helpful is the solid inspector. This plugin will scan your models for breaks in the surface and a few other problems and highlight them. This can save you a lot of time, especially if Shapeways is consistently rejecting your model.

Stay tuned for my next entry, where I'll explain how to make rounded surfaces!

Very useful, thanks for the info. I dont know if its possible, but is there a plugin for sketchup yet that will hollow out a complex shape? like if I want to design a 28mm figure and then have it hollowed out with a 2mm wall thickness?

ReplyDeleteThanks

I would love this, but unfortunately there are no plugins that do this. Everything has to be done by hand. It's not really hard, just time consuming.

ReplyDeleteIts not too bad for less complex models, but i've got a few models that are just way too complex to think about doing by hand, I live in hope of a decent plugin that will creat a shell of a model. it seems like something that should be possible, although of course its not something I can program myself. I can draw this kind of thing in sketchup: http://fc01.deviantart.net/fs16/f/2007/175/4/0/Scarab_Anti_Armour_Mecha_by_technoscream.jpg ...but without being able to create a shell or thin wall, it would cost way to much to print this model in 3D.

DeleteIt really comes down to the model's size and the material used. I'm definitely going to do a post on how to hollow out material by hand. You'll want each of those parts to be components (so head, body, legs, etc). Make a copy of the part, shrink it, then move it inside the main part and reverse its faces. Viola! Instantly hollowed.

DeleteThese are just some of the tricks I'm learning :)